|

|

Post by metroland on Nov 4, 2015 15:54:31 GMT

Welcome to Mantles Wood. Followers of my old layout will know that sadly I had to tear it up, in preparation for a house move to west Wales May 2014. The Head of Household gave approval for me to use the new garage as my layout room, a very commendable 17’ x 13’ area. However, it wasn’t until nearly Christmas that we were able to have local chippies convert it into a proper room, as we were endlessly moving furniture from room to room whilst the bungalow was re-decorated etc, and the garage was needed as decanting space. Why Mantles Wood? Well I’d always been fascinated by Rickmansworth ever since I discovered it as a lad, and as you know my old layout had elements of BR and LT. Even with my larger facility there’s no way I could attempt Ricky so was pondering a poor man’s Rickmansworth. Many of you will know that Mantles Wood marks the boundary these days between Network Rail and TfL, and in the past BR/LT etc. Needless to say Mantles Wood isn’t actually at Mantles Wood but then Clapham Junction isn’t at Clapham so nothing new there then. Further reading here: www.metadyne.co.uk/Mantleswood.htmlThis gave me the opportunity to have a name from the right area, but use my old stock and the old pretext that the line here was originally LNWR/Metropolitan Joint before eventually becoming BR/LT. The rest of this first post concerns the conversion of the garage into a proper room as I hope some viewers will be interested.

The garage was built in about 1999, with a typical concrete floor and breeze block construction, and a window that was little better than green-house glass. Fortunately we had a sum of money left over from the house move that meant paying for the job to be done properly wasn’t too onerous, although we avoided super-dooper professional firms who would have charged well who knows….? Although the bungalow wasn’t a wreck, we had a lot to do with thorough redecoration, and then (mostly through choice) rebuilding the kitchen, major re-wiring and replacing the fireplace. This gave us the chance to check out the price/quality of local tradesmen who generally did a good day’s work for a good day’s pay and by and large were semi-retired/almost retired. We decided to offer the work to a local carpenter who’d done good work for us, a shopfitter/chippie who he also used on bigger jobs, and an electrician who’d done a lot of wiring for us. Generally speaking their work was £12-£15 per hour (amazing considering where we’d come from in South Bucks). As the garage was all concrete/stone I decided to go for hi-spec within reason and I’m really glad I did. Note: I was quite ill when most of the work was done so quality of pics varies. I had the window replaced with a double-glazed one just before the major work was done. The walls and floors were covered with waterproof membranes. The flooring timbers were either 4” x 3” or 4” x 2” and the wall timbers were 3” x 2”. In both cases the spaces were filled with 40mm insulating foamy stuff which had waterproof facings. The walls were then covered with plasterboard and then plastered. The floor then had a covering of flooring quality chipboard. Also the living room carpet from the previous owner didn’t suit us indoors but it was fairly new and did a treat in the garage. The work was complete just before Christmas. It took a while for the top plaster to dry as it was damp weather at the time, however it was worth the wait. Touch wood there’s been no shrinkage to date since it dried so slowly. As the garage was a bare shell, the cost of additional wiring and sockets was minimal (as compared doing half the amount I eventually chose) so I had 16 electric sockets and eight 4’ fluorescent lights in 2 banks of 4. With the wiring that we’d had done in the main house, we’d had to have a new consumer unit (fuse box in old money). There was spare capacity on this to run a 40A cable to the garage so the electrician gave me another ring main in the garage with its own fuse box. I could actually have a cooker in there but that’s probably overkill unless I’m really in the doghouse. The ‘loft’ space was filled with something like 12” of rock-wool to give further insulation. Total cost of the work was in the region of £4k, roughly 50/50 parts/labour. Clearly that’s not the sort of sum most people have on tap, and neither did I before the house move. However that was by no means bad when you consider that people who advertise heavily about converting lofts/garages into meaningful space would like have wanted double. Even if you’re doing it yourself I’d strongly recommend doing it to a decent spec if funds allow. A couple of pics of the garage just prior to the work:  rev a unconverted garage 800px rev a unconverted garage 800px by Sarah S1ddons, on Flickr  rev b unconverted garage 800px rev b unconverted garage 800px by Sarah S1ddons, on Flickr Early wiring work before the build proper can start:  rev c start of wiring 800px rev c start of wiring 800px by Sarah S1ddons, on Flickr Roof and floor work. Note the garage door hasn’t yet been covered:  rev d roof 800px rev d roof 800px by Sarah S1ddons, on Flickr  rev e floor 800px rev e floor 800px by Sarah S1ddons, on Flickr The garage door has now disappeared behind a wall  rev f wall_garage door 800px rev f wall_garage door 800px by Sarah S1ddons, on Flickr Top-coat plastering under way on the end wall opposite the garage doors  rev g plastering in progress 800px rev g plastering in progress 800px by Sarah S1ddons, on Flickr The finished room but still bare  rev h complete_bare 800px rev h complete_bare 800px by Sarah S1ddons, on Flickr Layout baseboards installed (described in next posting). Also old kitchen units and work surfaces have been recycled to give a decent workbench in the middle.  rev i complete 800px rev i complete 800px by Sarah S1ddons, on Flickr Next posting: Initial track work |

|

|

|

Post by domh245 on Nov 4, 2015 16:09:52 GMT

Looks good. Looking forward to seeing more of it!

|

|

|

|

Post by metroland on Nov 4, 2015 16:47:22 GMT

Thanks. I've actually got 4(!) more updates in preparation.

I don't want to rain on anyone's parade but I get a bit irked when people put up their new layout/blog/gallery etc in a rush of enthusiasm and then don't follow through. I had decided not to post anything initially until I'd got enough to get beyond the prep work. Now I've got about 10 months progress there's a mini-mountain of writing to do. Hey ho....

|

|

|

|

Post by whistlekiller2000 on Nov 4, 2015 18:16:23 GMT

You can't beat a good train set I had one planned for my grandson in the loft but a small business got in the way - literally! Somebody else's train set , and one under construction at that, will do nicely as a proxy instead!

|

|

metman

Global Moderator

5056 05/12/1961-23/04/2012 RIP

Posts: 7,421

|

Post by metman on Nov 4, 2015 22:07:37 GMT

Thanks. I've actually got 4(!) more updates in preparation. I don't want to rain on anyone's parade but I get a bit irked when people put up their new layout/blog/gallery etc in a rush of enthusiasm and then don't follow through. I had decided not to post anything initially until I'd got enough to get beyond the prep work. Now I've got about 10 months progress there's a mini-mountain of writing to do. Hey ho.... Yeah sorry about that.....  |

|

|

|

Post by metroland on Nov 6, 2015 9:59:48 GMT

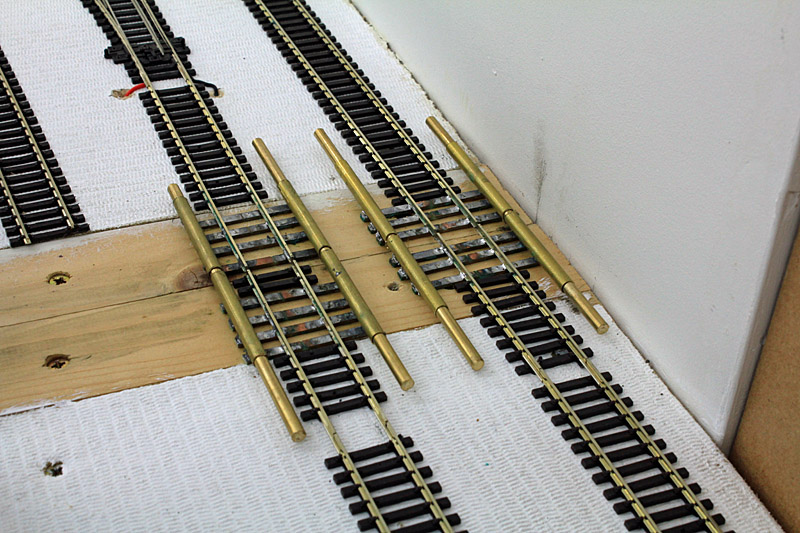

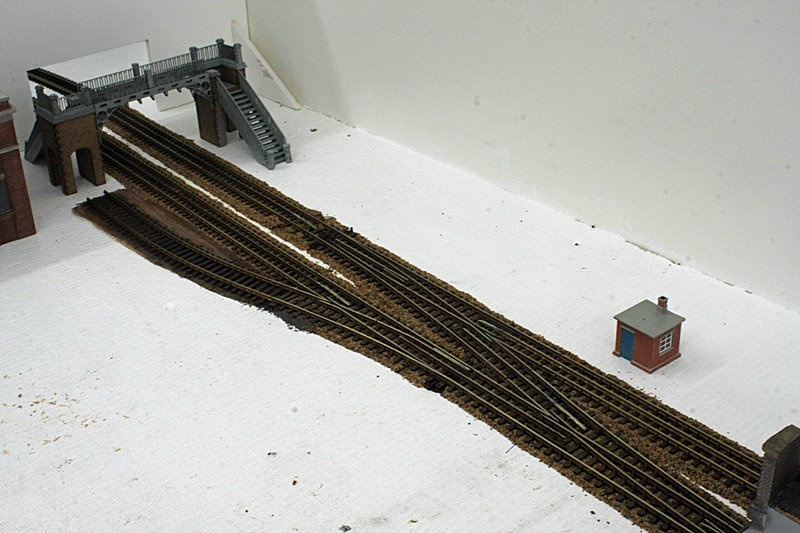

Welcome Back. (Initial Track Work) Finally in the spring I was able to think about track laying, but first of course I needed something to lay it on. I’d looked at various suppliers of kits for baseboards, some of which looked rather good, but having spent quite a bit on the garage conversion I felt there were just too many additional costs after what I’d already incurred. My carpentry skills are ok-ish but with a room this size I really wanted something decent to do it justice. Step forward (again) the local carpenter. He’d never done model railway baseboards. I was confident enough to work with open-frame baseboards this time round but he wasn’t. Basically he was confident with MDF. I’m sure he could have done open-frame boards but the time factor would have pushed the cost up. You can see from the last picture in my first post that he constructed a framework all around, with MDF ‘table’ on top. This only took him 3 and a half days to do an excellent job that I could never hope to match. I drove him a bit crazy with the lift-out section – it was quarter circle which (if not done properly) would have had a tendency to fall away outwards under gravity. The position/shape etc was dictated by the entry door position and my need to try and keep all ‘main line’ curves to 3’ radius or better. As I was planning to lay my own version of 4-rail, I needed a layer of half-inch insulation board on top, which I thought would be easy to source. After all that’s what I had before. Wrong! Most insulation board is now 40mm and/or some other material. Jewsons had some board in their catalogue but none in the local store in Llandysul (I’m out in the sticks now). They found some in stock at a branch elsewhere and several days later it was due to be delivered to the Llandysul branch. When they did it was all damaged….. Fair do’s to the local bloke behind the counter. He spent some time trying to source 8’ x 4’ x 1/2inch insulation/fibre boards and eventually found some and I had them delivered. The carpenter was then able to cut them and fit them quickly as he had the in-situ baseboards as templates. I was now able to test track configurations…. or not…….. I’d used Anyrail program to plan my layout (no disrespect to SCARM but I just couldn’t get on with it). So I was ready to try some general arrangements.  rev a IMG_1272 unpainted board rev a IMG_1272 unpainted board by Sarah S1ddons, on Flickr You may not be able to see from this pic but the insulation board is very finely rippled – a bit like the patterns you see in compacted sand when the tide goes out. This was creating quite a bit of very fine dust and looked like it would be a problem over time. Consequently I had to spend several more days covering it with a coat of wallpaper paste then 2 coats of white emulsion. The next few pics are a bit bland but give you an idea of what should be evolving. I have a lot of stock but was wary of over-complicating the layout and wanted something running before too long (ie before I got bored with track-laying etc). In effect I have 2 sides with ‘scenery’ (or will have) and 2 sides for storage. (In practice I have about 14’ of one 17’ side, a full 13’ side, and 3’ of another 17’ side). Two views of the intended station area  rev b view 800px rev b view 800px by Sarah S1ddons, on Flickr  rev c view 800px rev c view 800px by Sarah S1ddons, on Flickr Through lines with siding, Up and Down Goods loop, and entrance to goods yard.  rev d UandD Loops 800px rev d UandD Loops 800px by Sarah S1ddons, on Flickr Storage roads by window (with sun cover).  rev e window a 800px rev e window a 800px by Sarah S1ddons, on Flickr Storage roads on end wall.  rev f passing loops 800px rev f passing loops 800px by Sarah S1ddons, on Flickr So following the KISS principle the scenic part of the layout is 2 through lines, a bay platform at the station with facing crossover. Facing and trailing crossovers for the U and D goods loops/goods yard, plus some simple sidings and headshunts. It may not be terribly clear, but on the main lines I used Tracklay under the track which I’ve used before and find is a boon to easy ballasting (well when I say easy, I suppose all things are relative…..) tracklay.co.uk/(No connection other than a happy user on 2 layouts) Needless to say Track is Peco Streamline Code 100 which I’m happy with. I like the ‘plug and play’ simplicity, but even so, it works, and I feel you can do a lot to make it reasonably convincing. With the exception of a few turnouts for short sidings and headshunts all turnouts on the main circuit are either large or medium radius. I’m fortunate to have the room to do this and it’s a great aid to smooth running. In fact from late July onwards, once I’d got 2 complete circuits running, I was able to test the trackwork extensively (not play you understand). Such is the beauty (to me) of Code 100 that anything which plays up now has to be a problem with the stock not the track. With a variety of RTR and kitbuilt stock, and various couplings etc problems arise from wheel back-to-backs, couplings and buffer lock, but at least if I have troublesome trucks now I can be confident I need to work on the rolling stock, not the track. The one area that was terrifying me was the 2 main lines traversing the lift out section.  rev g lift-out section rev g lift-out section by Sarah S1ddons, on Flickr The poor old carpenter couldn’t really understand the need to have wood at the ends with insulation board inlaid for the rest of the trackbed but he made a good job of it. My soldering isn’t terribly elegant but you can see I followed a traditional route of replacing plastic sleepers with copper ones (scored top and bottom to avoid shorts!) These were then glued to wood, not insulation board. To these I soldered brass tubes which had rods inside as an interference fit. Then I cut the tubes and reinserted the rods. Hey presto! Physical and electrical alignment. I’m sure there are more elegant ways of doing this but I’m a pragmatist and the lift out section is in the non-scenic area, and it works (so far…. 4 months and counting….) Next posting – Track weathering, and ballasting. |

|

|

|

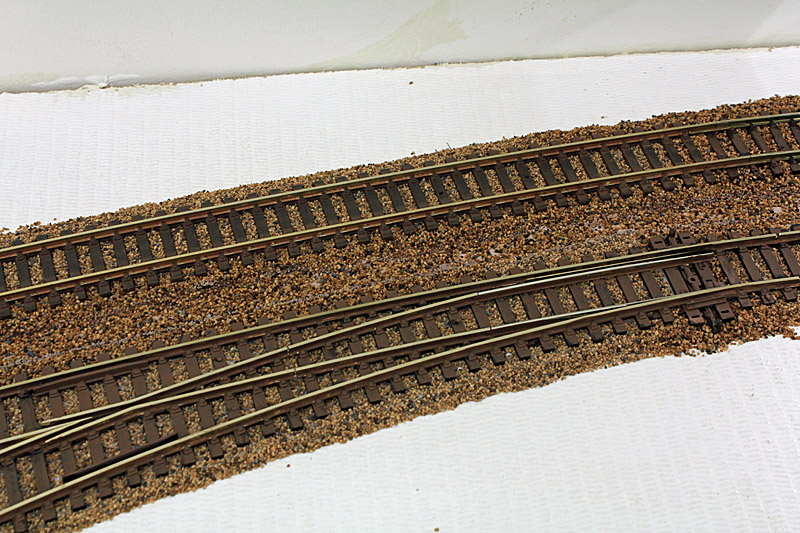

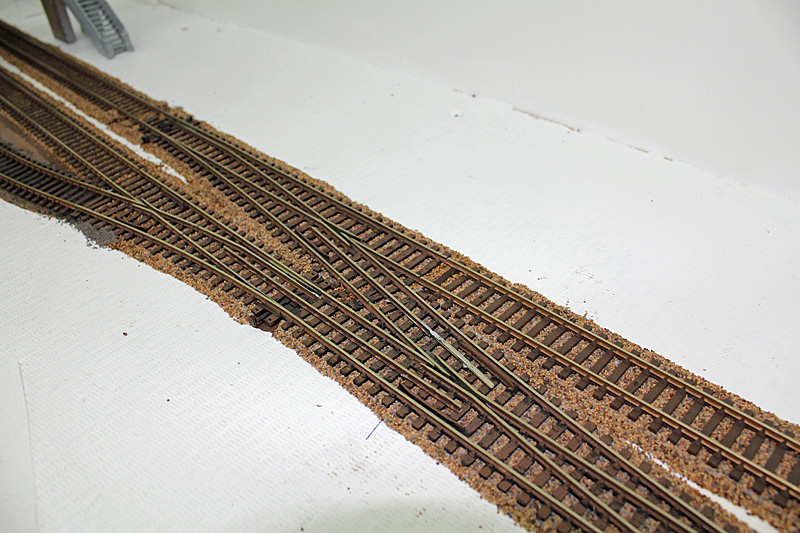

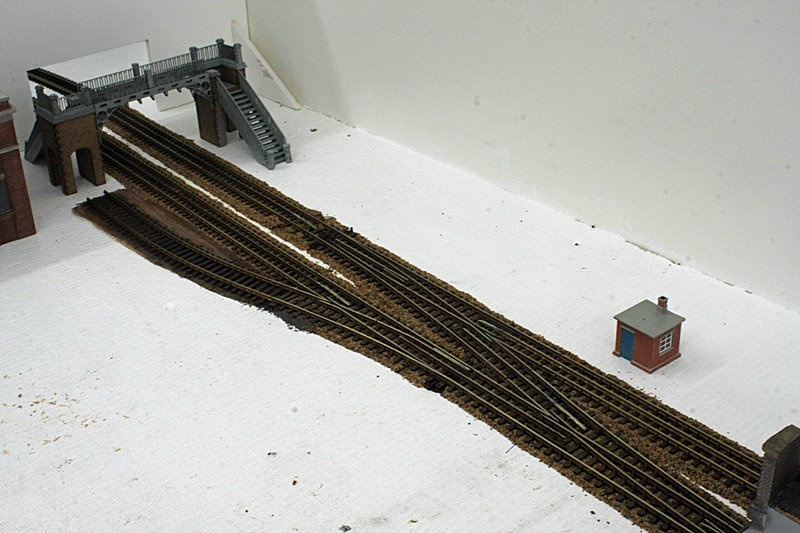

Post by metroland on Nov 8, 2015 11:23:41 GMT

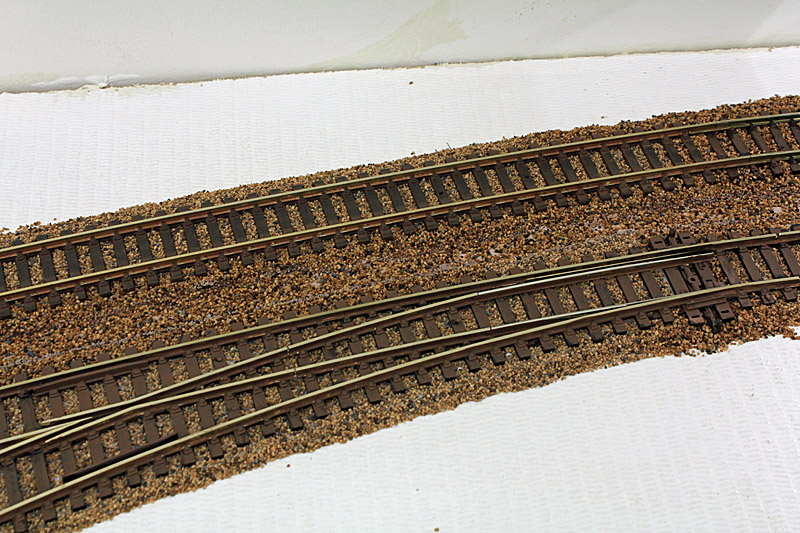

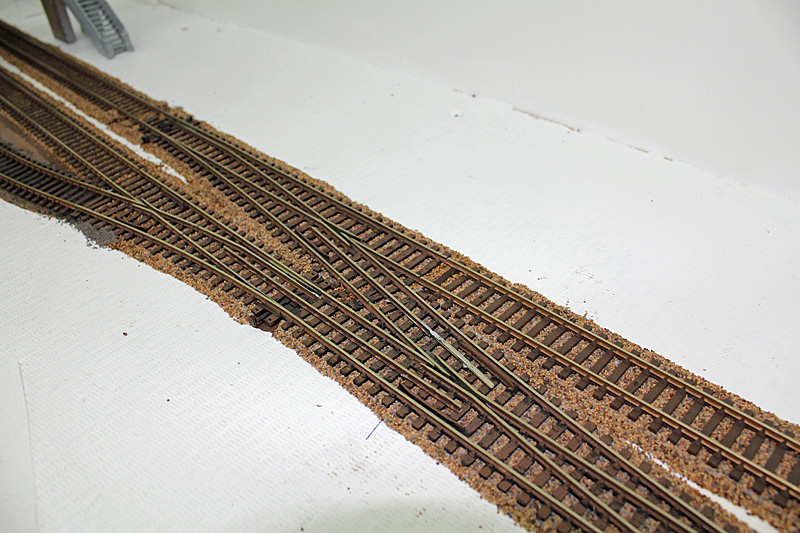

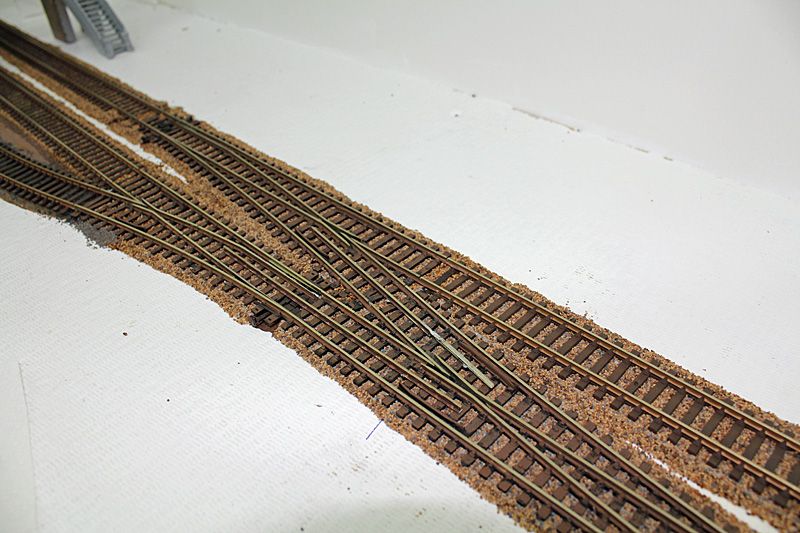

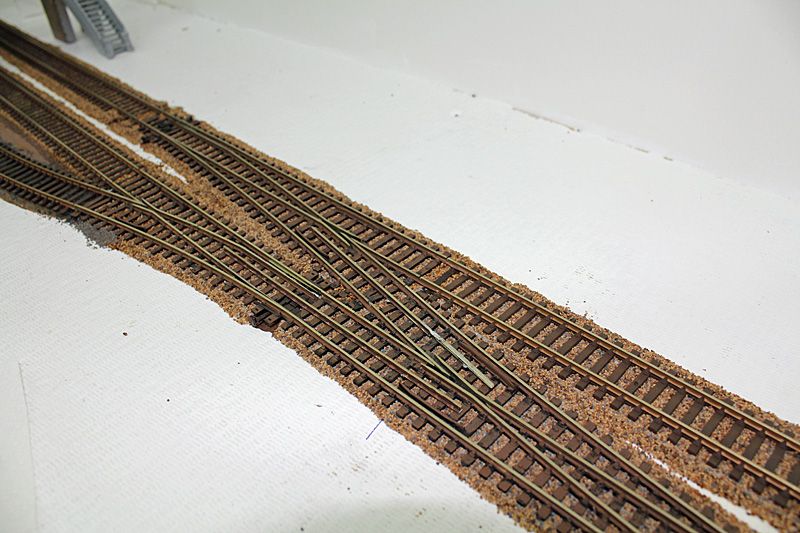

Initial ballasting, and track weathering. Those of you that remember my old layout will recall that I don’t profess to have any great skill levels and am always looking to create the right ‘look and feel’ without being a master-builder. To this end there’s been some evolution to my trackwork. The first change is to get some quick weathering to the track. On youtube I discovered people spraying their track with Tamiya TS1 red/brown. This year I sprayed most track with a dusting of this before laying (don’t forget to wipe the top of the rails before it hardens!)  rev a Tamiya Spray 800px rev a Tamiya Spray 800px by Sarah S1ddons, on Flickr The 2nd change is to use ready-mixed ballast. I the past I mixed my own as I wasn’t happy with most commercial offerings. However I discovered Carrs sand-stone mix which I’ve used on this layout. Note: it appears a bit more orangey in these pics than to the naked eye.  rev b Carrs ballast 800px rev b Carrs ballast 800px by Sarah S1ddons, on Flickr The main thing to remember this isn’t the end of weathering ballast or track but it does give a reasonable and reasonably quick way of getting something down that looks ok for now, and I don’t need to come back to it until after I’ve done 101 other jobs.  rev c ballasted track 800px rev c ballasted track 800px by Sarah S1ddons, on Flickr The sidings and passing loops here need to be ballasted to a lesser standard hence all the white underneath some track.  rev d ballasted track 800px rev d ballasted track 800px by Sarah S1ddons, on Flickr |

|

|

|

Post by metroland on Nov 11, 2015 9:37:07 GMT

|

|

|

|

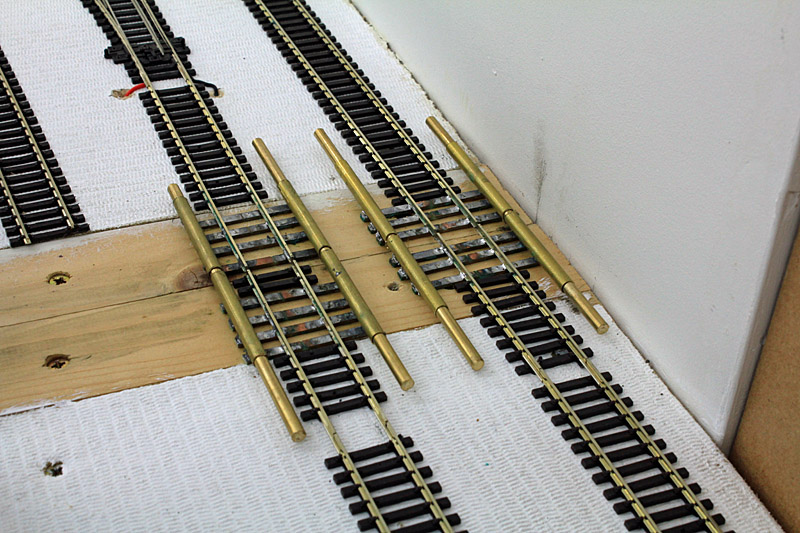

Post by metroland on Dec 10, 2015 15:23:06 GMT

OK the time has come to start 3rd and 4th rail track-laying. Laying the centre rail has taken place during November and part of December. On my old layout I glued the centre rail to the sleepers. This was generally successful but I’m trying another way this time. On the real thing the centre rail is elevated approx. 3” compared with the running rails but as that’s only 1mm there’s no way I’m going for super accuracy. However, on my old layout the centre rails didn’t have to curve much, just eg into bay platforms. On this layout they have to do a complete 90deg turn for the ‘electrified tracks’ to reach the turnback siding, so glueing probably won’t stand the test of time. For the centre rails (these are much too clunky for normal track-laying) I’ve used Gaugemaster ‘Hornby’ pins.  Centre 1 800px Centre 1 800px by Sarah S1ddons, on Flickr I then added a blob of solder to the heads.  Centre 2 800px Centre 2 800px by Sarah S1ddons, on Flickr Pins are then pushed into the ballast between sleepers. It doesn’t matter (in fact it can be quite helpful) if the pins are some way proud of sleeper level at this stage.  Centre 3 800px Centre 3 800px by Sarah S1ddons, on Flickr Solder the centre rail to the pins and then push the whole ensemble down to the correct height. I recycled some rail from the old layout here so the rail needs re-weathering, but hopefully shows the principle. A facing crossover taking shape.  Centre 4 800px Centre 4 800px by Sarah S1ddons, on Flickr  Centre 5 800px Centre 5 800px by Sarah S1ddons, on Flickr I’ve started using C&L Finescale ramps. At £7 for 4 they’re not cheap (but then brass castings are never cheap these days). Here’s a close up of one attached to some new rail. I’m hoping that further weathering and ballasting will provide some visual tricks to take the eye away from the joins where these ramps need to be soldered onto Peco rail.  Centre 6 800px Centre 6 800px by Sarah S1ddons, on Flickr The C&L ramps aren’t designed to fit end-on to Peco100 so there’s still work to be done blending/disguising the joins. A few pics of progress to date: The London end:  rev a IMG_1389 rev a IMG_1389 by Sarah S1ddons, on Flickr At ground level:  rev b IMG_1389 rev b IMG_1389 by Sarah S1ddons, on Flickr Loco servicing sidings  rev c IMG_1389 rev c IMG_1389 by Sarah S1ddons, on Flickr Approaching the turnback siding:  rev d IMG_1389 rev d IMG_1389 by Sarah S1ddons, on Flickr The turnback siding:  rev e IMG_1389 rev e IMG_1389 by Sarah S1ddons, on Flickr |

|

|

|

Post by whistlekiller2000 on Dec 10, 2015 15:47:12 GMT

I'd be interested to see the layout plan you initially generated.  |

|

|

|

Post by metroland on Dec 11, 2015 9:54:17 GMT

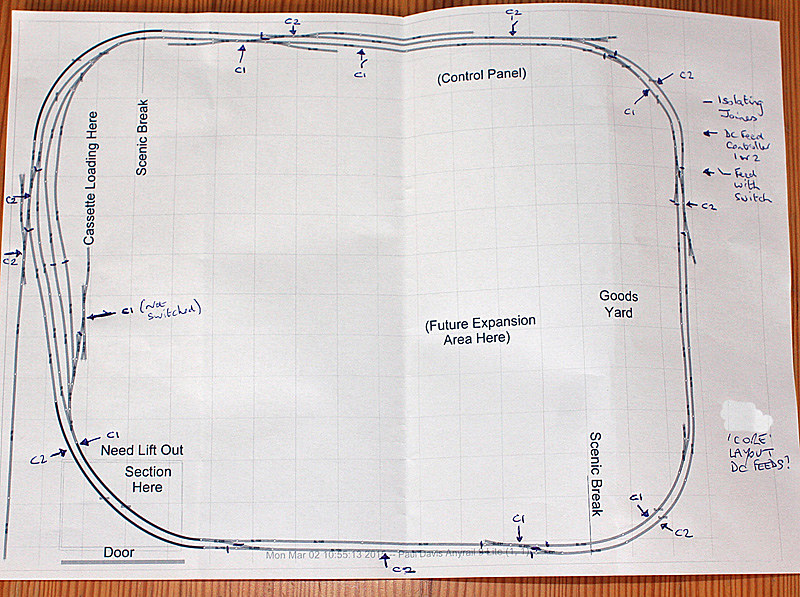

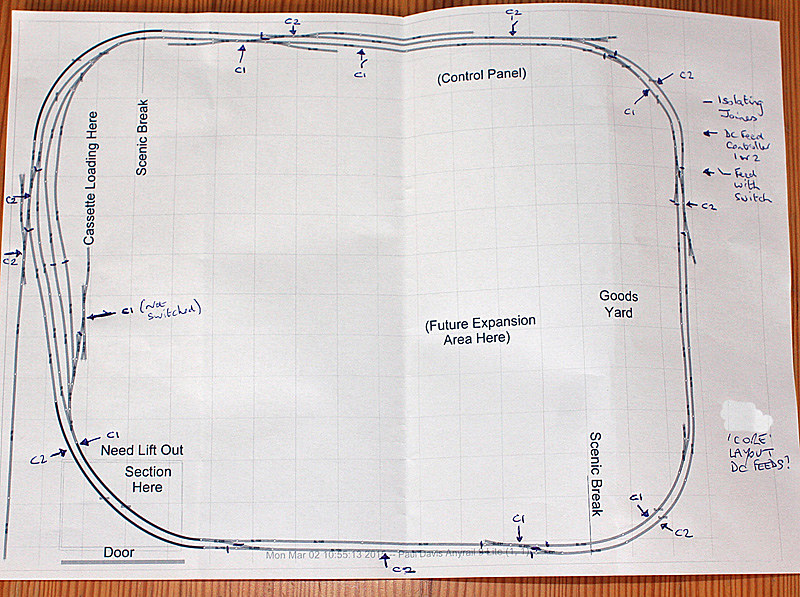

This is the simplified plan I used for initial track-laying. The outer circuit is Down, powered by controller C2 and the inner circuit is UP/C1. Track is Peco code 100 Electofrog and shows the power feeds (DC) and insulating breaks. The scenic section goes from 11 o’clock to 5 o’c clock. Generally sidings and passing loops are not shown as they were added/modified later. The long bay platform at 12 o’clock didn’t work, so the longer of the 2 spurs on the Up side was made the bay, and the crossover changed from trailing to facing so trains from ‘London’ could cross from Down to Up and enter the bay. Points are shown for 2 potential turnback sidings at 3 o’clock but in the event I felt it worked better with just one turnback line. The facing crossover at 5 o’clock was never laid as I changed the storage siding arrangement along that wall. Lots more sidings were laid along the LH side for storage and a trailing crossover added at 10 o’clock between the Up and Down lines so I can run stock from pretty much any stabling point to any other – subject to train length.  rev ver 9-Lite DC electric feeds rev ver 9-Lite DC electric feeds by Sarah S1ddons, on Flickr |

|

|

|

Post by metroland on Jan 13, 2016 11:10:49 GMT

Unfortunately my wife had a week in hospital in December which meant progress since the last update has been slow. I’ve now installed outer conductor rail at the entrance to the turnback siding, and the crossover for trains to exit and return to ‘London’.  rev IMG_1399 800px rev IMG_1399 800px by Sarah S1ddons, on Flickr |

|

|

|

Post by theblackferret on Jan 13, 2016 11:21:55 GMT

Unfortunately my wife had a week in hospital in December which meant progress since the last update has been slow. I’ve now installed outer conductor rail at the entrance to the turnback siding, and the crossover for trains to exit and return to ‘London’.  Hope your wife's feeling better, and thanks for the updates, because it's fascinating watching a work of art develop over a long timescale. Bit like the medieval craftsmen and stained glass windows. |

|

|

|

Post by metroland on Feb 6, 2016 13:45:18 GMT

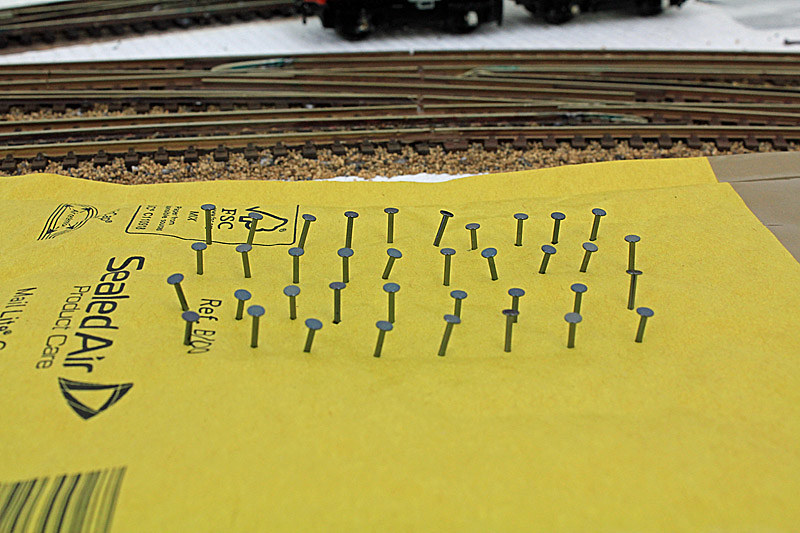

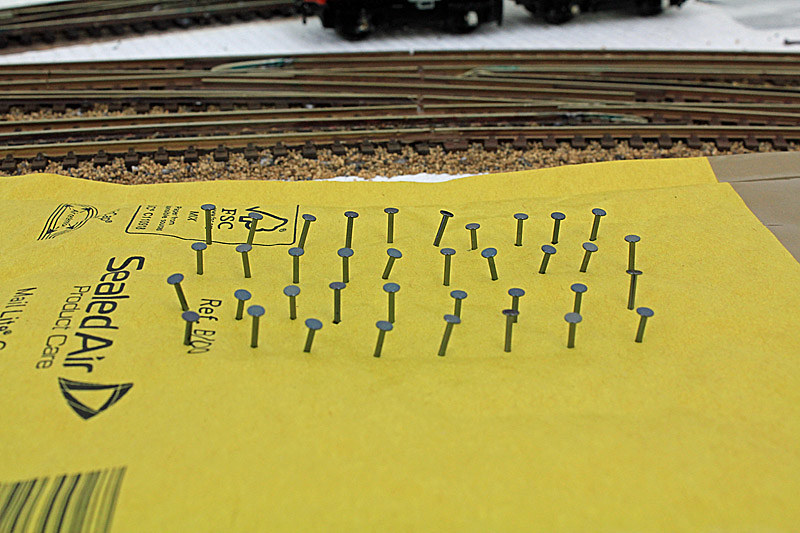

I’ve been able to make progress with the outer conductor rails in January. The work isn’t yet finished, but here’s an update. On my old layout I used N gauge track for the outer rail (Code 60). This was glued to Peco track pins and took quite a while to do, as it wasn’t easy keeping the track on the pins whilst the glue hardened. It had been suggested that I should solder the rails to the pins. I was going to use this method on Mantles Wood, but I found that I couldn’t actually solder anything to the Peco track pins, so back to the drawing board….. I had quite a bit of Peco HOm track lying around from another project which is Code 75 rail so I decided to give this a go for the outer rails. Of course Code 75 is available in its own right as Peco OO finescale so you don’t need to seek out HOm. After a few experiments I continued using the Gaugemaster track pins which are quite chunky but actually have helped here. (Bear in mind I’m no engineer and always looking to apply the KISS principle to create the look and feel of 4 rail track whilst working within my own limits and the fact that OO track is only 4’2” wide). For outer conductor rail an insulating pot is needed every 5 sleepers or so, and with over 60’ of track to do, that’s quite a bit of tinning and soldering. In order to tin batches of pins I hit upon the simple solution of using old jiffy envelopes. A few dozen pins at a time can be held in place whilst flux and solder is added to the heads.  Outer 1 800px Outer 1 800px by Sarah S1ddons, on Flickr The relatively wide heads of these pins turned out to be quite an advantage. If I solder the rail to the pin and got the rail too close/far from the running rail I had room to unsolder the joint and move it slightly. Bearing in mind that most pots disappear under grime, adding a dab of off-white colour to some of the pins hopefully makes them look like pots from a normal viewing distance. A couple of wider shots of the junction shown in my previous posting:  Outer 2 800px Outer 2 800px by Sarah S1ddons, on Flickr  Outer 3 800px Outer 3 800px by Sarah S1ddons, on Flickr On my previous layout I didn’t have to lay 4 rail track on any really difficult curves. I had a bay platform, and a siding, both of which had gentle curves. On Mantles Wood I have 2 concentric curves of 3’ radius turning through a right angle. I wasn’t looking forwards to this, but in fact after having had some practice with the new method on easier sections, this didn’t go too badly. Some joins had to be re-soldered, but again from a reasonable distance they pass muster – I hope. Most of the curve is shown here.  Outer 4 800px Outer 4 800px by Sarah S1ddons, on Flickr A close-up of the track at the western/northern end of the curve.  Outer 5 800px Outer 5 800px by Sarah S1ddons, on Flickr Because Rickmansworth station is on a tight-ish curve it’s difficult to find pictures showing the whole length of rail without trains covering most of the tracks. So far as I can tell both the centre and outer conductor rails do not have any breaks and continue unbroken alongside the whole length of the platforms. Although I’m not doing Rickmansworth this does mean I have 2 x 8’ runs which need 4 rail and of course no-one makes rail in that length. I wasn’t looking forwards to this either. I’ve now done the Down side. This meant I had to solder 3 lengths of Code 75 together, and cut to length. I’m quite pleased with this (the outer rail has not been weathered yet).  Outer 6 800px Outer 6 800px by Sarah S1ddons, on Flickr A cruel close-up of one join in the outer rail. Hopefully a bit of careful sanding and then weathering will disguise the join.  Outer 7 800px Outer 7 800px by Sarah S1ddons, on Flickr As I’ve said so many times, I’m no engineer, simply trying to get the look and feel of 4 rail in OO, without the need for any specialist tools or skills. Hopefully some of you will be encouraged to experiment. |

|

|

|

Post by theblackferret on Feb 6, 2016 15:49:57 GMT

Wow!

Continues to be fascinating to follow.

Incidentally, would enamel or just possibly masonary paint in a matching shade on those soldered joins be acceptable after sanding?

|

|

|

|

Post by bassmike on Feb 6, 2016 15:52:16 GMT

OK the time has come to start 3rd and 4th rail track-laying. Laying the centre rail has taken place during November and part of December. On my old layout I glued the centre rail to the sleepers. This was generally successful but I’m trying another way this time. On the real thing the centre rail is elevated approx. 3” compared with the running rails but as that’s only 1mm there’s no way I’m going for super accuracy. However, on my old layout the centre rails didn’t have to curve much, just eg into bay platforms. On this layout they have to do a complete 90deg turn for the ‘electrified tracks’ to reach the turnback siding, so glueing probably won’t stand the test of time. For the centre rails (these are much too clunky for normal track-laying) I’ve used Gaugemaster ‘Hornby’ pins.  I then added a blob of solder to the heads.  Pins are then pushed into the ballast between sleepers. It doesn’t matter (in fact it can be quite helpful) if the pins are some way proud of sleeper level at this stage.  Solder the centre rail to the pins and then push the whole ensemble down to the correct height. I recycled some rail from the old layout here so the rail needs re-weathering, but hopefully shows the principle. A facing crossover taking shape.   I’ve started using C&L Finescale ramps. At £7 for 4 they’re not cheap (but then brass castings are never cheap these days). Here’s a close up of one attached to some new rail. I’m hoping that further weathering and ballasting will provide some visual tricks to take the eye away from the joins where these ramps need to be soldered onto Peco rail.  The C&L ramps aren’t designed to fit end-on to Peco100 so there’s still work to be done blending/disguising the joins. A few pics of progress to date: The London end:  At ground level:  Loco servicing sidings:  Approaching the turnback siding:  The turnback siding:  |

|

|

|

Post by bassmike on Feb 6, 2016 15:54:36 GMT

I think the centre rail is 1 -I/2" above r/ rails not 3"

|

|

|

|

Post by metroland on Feb 6, 2016 15:58:23 GMT

Wow! Continues to be fascinating to follow. Incidentally, would enamel or just possibly masonary paint in a matching shade on those soldered joins be acceptable after sanding? I use a small pot of acrylic Tamiya rusty brown which is the same shade as the spray can. You can just see a pot of it in the pic after the phrase 'approaching the turnback siding'. Nickel silver track is a bit funny, sometimes paints stick and sometimes not. I suspect an enamel paint may need and undercoat/primer. |

|

|

|

Post by metroland on Feb 6, 2016 16:00:30 GMT

I think the centre rail is 1 -I/2" above r/ rails not 3" OK but that's 0.5mm difference between the two? Way betond my skill level! |

|

|

|

Post by Dstock7080 on Feb 6, 2016 18:23:25 GMT

I think the centre rail is 1 -I/2" above r/ rails not 3"

To allow top contact current collection without the shoes fouling the running rails, the current rails are arranged so that their top surface is higher than that of the running rails, by 3 inches (76mm) in the case of the positive rail and by 1.5 inches (38mm) for the negative.

In the tunnel sections of the Central line, the positive rail is placed a further 1.5 inches (38mm) above the running rails, due to limited clearances in this section dating from enlargement of the original Central London Railway tunnels. |

|

DWS

every second count's

Posts: 2,487

|

Post by DWS on Feb 7, 2016 8:26:30 GMT

The Central line tunnels east of Liverpool Street were built as part of the New Works plan to extend the line to Stratford and Epping, and are built to are larger size than the ex Cental London Railway, I think that in these tunnels that the positive current rail is at the standard hight above the running rails.

|

|

|

|

Post by metroland on Jul 18, 2016 15:43:01 GMT

I thought it was about time I did an update. Some of you asked about the ‘performance’ of the garage. We had a relatively mild but very wet winter. I live about 20 miles from Eglwyswrw (pronounced eggla-sooroo) which you may have seen in the news early 2016 as it nearly gained the record for the most continuous days rain in the UK…. In general, the 10am temp in the garage was about +4C though on a couple of very cold nights this dropped to +2C. By early March though, the 10am temp was a creditable +7C, a position from which the room heated up quite quickly. If anyone is considering a garage conversion I’d recommend a high-spec finish if you can afford it. So far as I can tell the 3rd and 4th rails haven’t buckled due to temperature variations though some were a bit wonky – probably because I rushed some of the later work. Quite a bit of time has been spent correcting bits I should have done better in the first place, and I’ve redone the weathering on several lengths of rail – a tedious but eventually rewarding task! My attention has lately turned to getting the platforms done which as always involves compromises. I’m lucky enough to be able to have quite long platforms (approx. 6’ 6”). The down side of this is, what do I use to get a realistic coverage of the platform surface? Various manufacturers offer products but these are always quite short relative to my needs and would mean a join or joins which I would like to avoid. Some people have made realistic surfaces of smooth asphalt with eg DAS modelling clay but again, there’s no way I could make a 6’ 6” length look adequate. Another problem again, is the fact that most ballast is way too large and ‘grainy’ to represent a platform surface. I’ve used ½” insulation board which I had left over from my old layout. Overview of platform area:  rev Platform overview 800px rev Platform overview 800px by Sarah S1ddonsWhat you can’t see from the pic is the narrow platform was first sealed with PVA before grey undercoat was applied. The front face was also sealed which should help with attaching the facing later. I had a supply of Carrs 2mm grey ballast but this was really too coarse, however I hit upon Busch quarzsand 7524 in black (they don’t seem to do a grey).  rev Carrs_Busch comparison 800px rev Carrs_Busch comparison 800px by Sarah S1ddons, on Flickr The platform was then covered again with PVA and the quarzsand liberally sprinkled on top. (Yes I know the bench needs tidying, don’t nag…..)  rev Platform Busch quartzsand 800px rev Platform Busch quartzsand 800px by Sarah S1ddons, on Flickr Some shots of it in situ after 24 hours and the excess had been shaken off.  rev Platform plus goods 800px rev Platform plus goods 800px by Sarah S1ddons, on Flickr  rev Platform plus goods high 2 800px rev Platform plus goods high 2 800px by Sarah S1ddons, on Flickr One of the things about asphalt is that when it’s laid, it tends to be black, but after a lot of traffic has worn it down it goes grey, except where there’s little use. This final shot shows an early attempt to try and get this effect on the end ramp. This was done with brushes and really needs an airbrush to get it looking more correct.  rev Platform plus goods incl ramp 800px rev Platform plus goods incl ramp 800px by Sarah S1ddons, on Flickr |

|

|

|

Post by theblackferret on Jul 18, 2016 21:18:14 GMT

1.You'll be finished & open before Crossrail at this rate-brilliant!

2.You seem to've found a use for Mike Ashley from the photos.

|

|

|

|

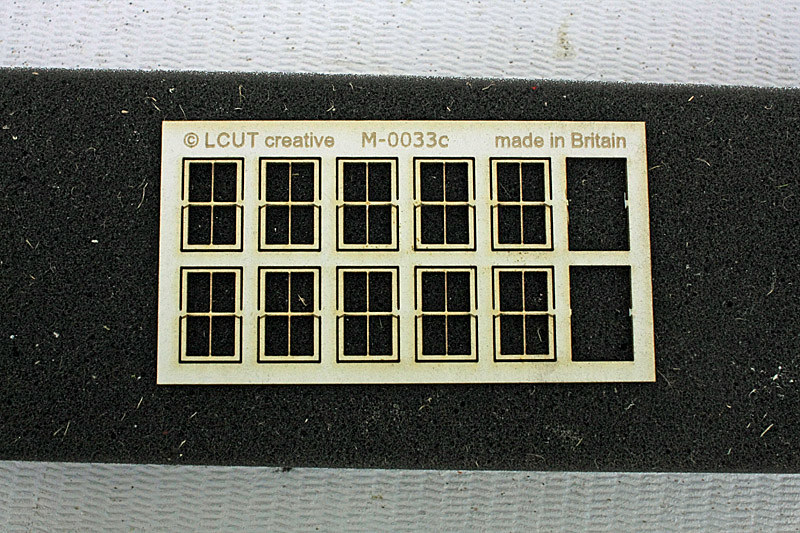

Post by metroland on Aug 18, 2016 9:22:05 GMT

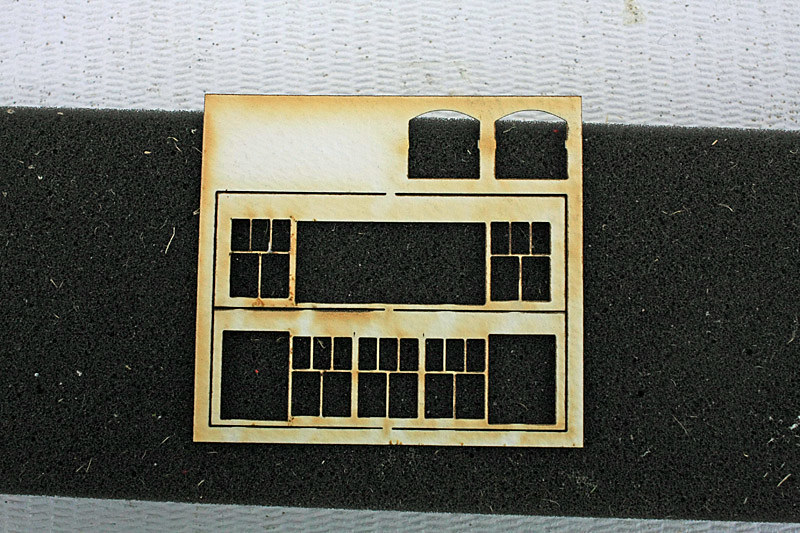

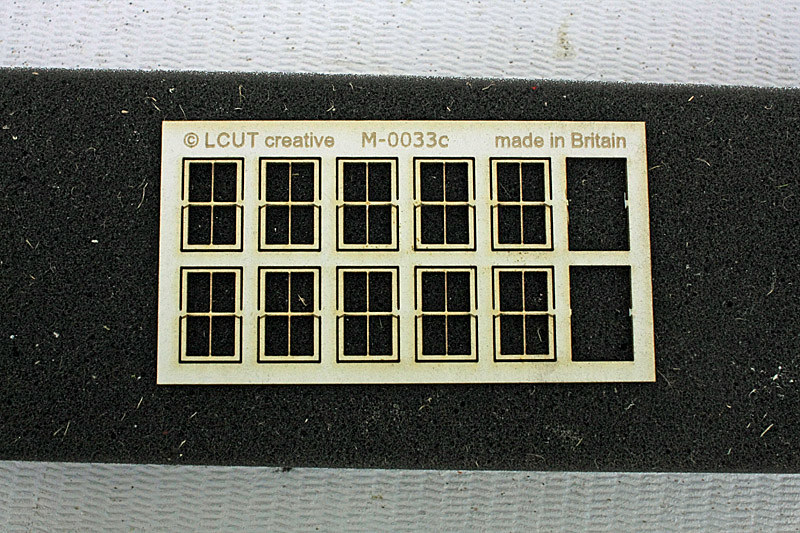

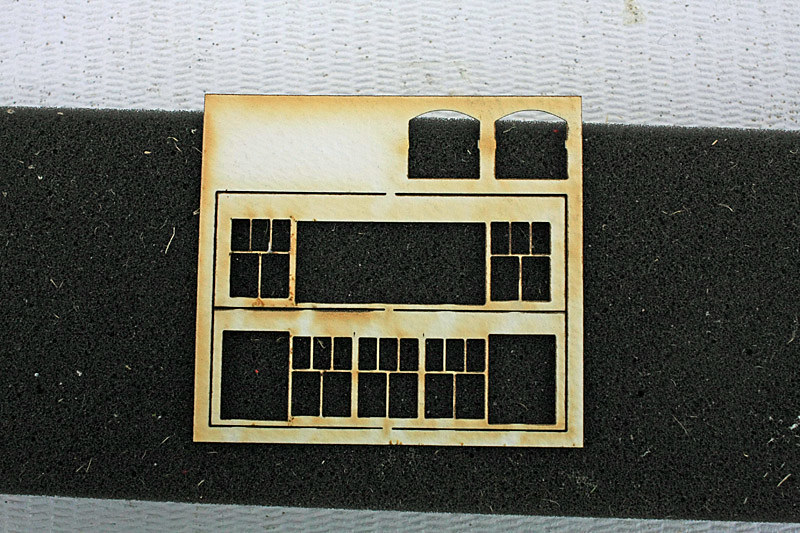

I wanted a fairly small signal cabin for the London end of the station, something like the size of Rickmansworth or Chorleywood. As the back-story is along the lines of it being a joint Metropolitan/LNWR line there was no such thing as a prototypical signal cabin. Metropolitan boxes were wooden with ‘4 square’ windows. LNWR boxes were generally brick base with wooden boards on the top half and more complicated windows. I thought I’d found the answer in that ABM Railcraft started doing SECR boxes which were the same as some District Railway cabins and the right size. Unfortunately the owner became ill and closed the business. Scratchbuilding is beyond me at the moment but I’m up for some butchering. LCUT Creative make a number of buildings in laser-cut material and I bought the signal cabin LCC B OO-03 which was a good size for the position. Unfortunately the windows are GWR style with 3 small windows over 2 large ones. Fortunately LCUT sell all sorts of building parts and they had some ‘4 square’ windows.  rev1 windows as supplied 800px rev1 windows as supplied 800px by Sarah S1ddons, on Flickr Until I got them on the bench I hadn’t realised the new windows were a different size from the ones supplied with the kit so some very careful scalpel work was needed to make them fit. (The material is VERY thin, especially the widow bars).  rev2 4 square windows 800px rev2 4 square windows 800px by Sarah S1ddons, on Flickr Some while later I had a partially-built kit to check the ‘footprint’ and I was happy with this.  rev3 initial placement test 800px rev3 initial placement test 800px by Sarah S1ddons, on Flickr After a few more hours squinting and cursing, I had the overall structure.  rev4 structurally complete 800px rev4 structurally complete 800px by Sarah S1ddons, on Flickr I decided to enhance the planking as it’s quite feint to the naked eye (though appears quite good in the previous photo). Redutex make a planking sheet though only in brown AFAIK so some was cut to shape and painted off-white. Woodwork was painted off-white or maroon as appropriate. (Note the roof is only plonked on and not finally positioned in the next 2 pics). The brickwork was then coloured and weathered.  rev5 painted_weathered a 800px rev5 painted_weathered a 800px by Sarah S1ddons, on Flickr For the BR maroon I used Testors Long Island Maroon which I felt was a good match for weathered paint on buildings. A comparison here with a Skaledale shelter shows it to be a good match (though the cream will have to change on the shelter).  rev6 painted_weathered b 800px rev6 painted_weathered b 800px by Sarah S1ddons, on Flickr I’ll leave it for now apart for a couple of minor tweaks which are still to be done. I have half a mind to extend the wooden planking to just below the main windows as that would make it more like LNWR but I’m happy with the compromise for now. |

|

|

|

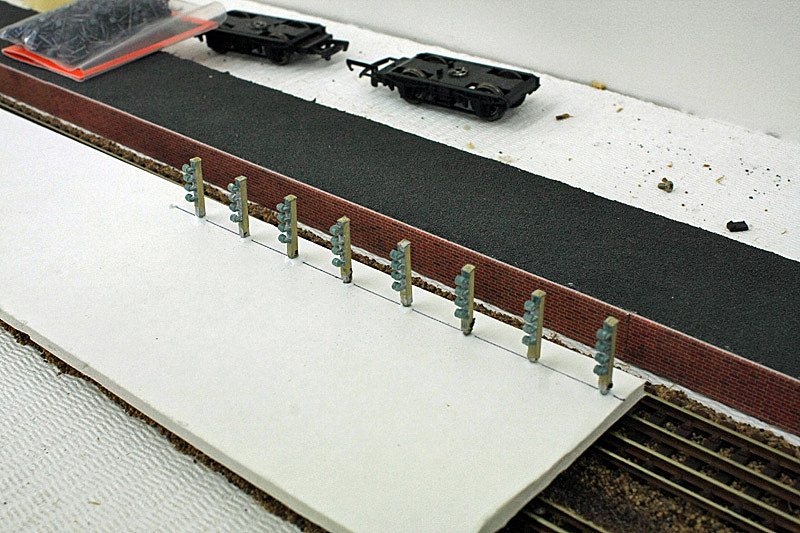

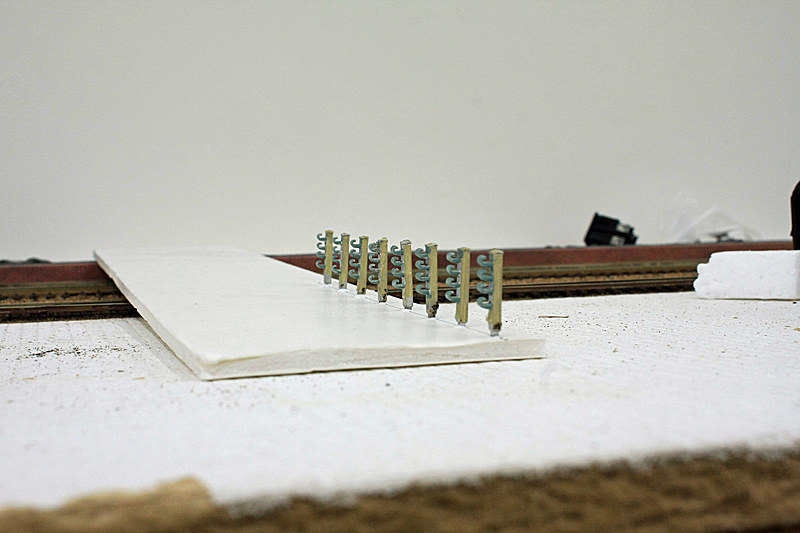

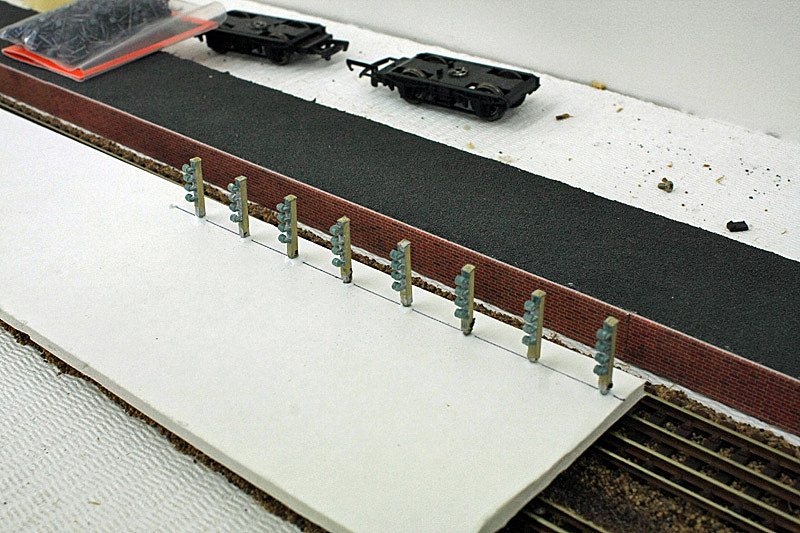

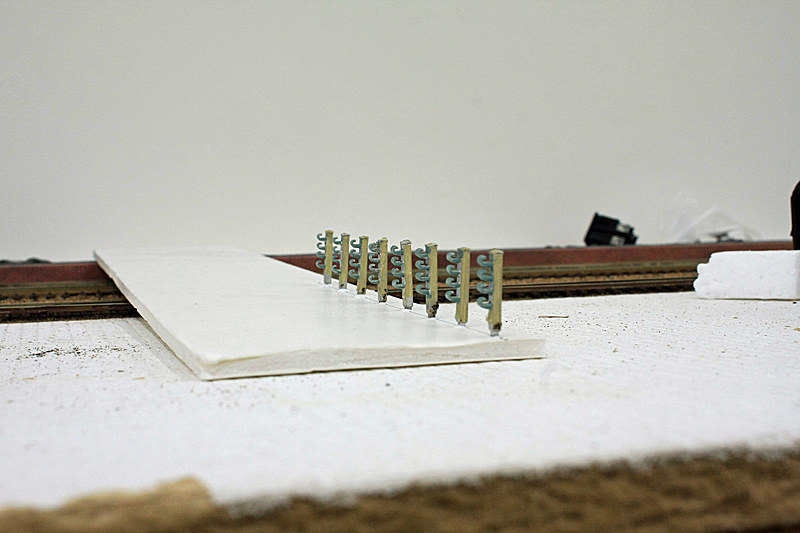

Post by metroland on Aug 29, 2016 13:19:29 GMT

Just a little update to show some practice work. On my previous layout I installed the lineside cabling quite early, but this involved quite a bit of stretching with the electric drill to reach awkward corners. Although I don’t have to stretch so far on this layout, I am expecting to have some tricky shapes. Sooo as is my custom I’ve spent some time trying to find an easy way to do this. As an experiment I drilled a line of holes in some foam-board (also called artist’s board and Dahler board I think). It doesn’t matter that the ‘peg’ in the Radley Models posts sticks a little bit proud as this is a practice, and in any case I’m thinking it would be covered by ground material. A little blob of PVA holds the peg in place. My thinking is that I should be able to create runs of cabling on the workbench, and then offer them up to layout, thus being able to work from both sides if needed.  rev Posts plan view 800px rev Posts plan view 800px by Sarah S1ddons, on Flickr  rev Posts end view 800px rev Posts end view 800px by Sarah S1ddons, on Flickr |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 26, 2016 0:33:47 GMT

Been away from here for a while but just seen the pictures of your progress. Wonderful stuff. Love the Q stock.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 26, 2016 0:35:29 GMT

What is the origin of your Hurst-Nelson Brake Van?

|

|

|

|

Post by metroland on Oct 2, 2016 18:37:47 GMT

What is the origin of your Hurst-Nelson Brake Van? Thanks, I've been away myself so only just seen your note. The duckets are from a Smallbrook Studios LSWR Road/Brake Van, grafted onto a Parkside LMS Brake (D.1659). I should have sanded the duckets smooth of course! |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 6, 2016 22:46:32 GMT

Very nice work.

|

|

rev a unconverted garage 800px by Sarah S1ddons, on Flickr

rev a unconverted garage 800px by Sarah S1ddons, on Flickr rev b unconverted garage 800px by Sarah S1ddons, on Flickr

rev b unconverted garage 800px by Sarah S1ddons, on Flickr rev c start of wiring 800px by Sarah S1ddons, on Flickr

rev c start of wiring 800px by Sarah S1ddons, on Flickr rev d roof 800px by Sarah S1ddons, on Flickr

rev d roof 800px by Sarah S1ddons, on Flickr rev e floor 800px by Sarah S1ddons, on Flickr

rev e floor 800px by Sarah S1ddons, on Flickr rev f wall_garage door 800px by Sarah S1ddons, on Flickr

rev f wall_garage door 800px by Sarah S1ddons, on Flickr rev g plastering in progress 800px by Sarah S1ddons, on Flickr

rev g plastering in progress 800px by Sarah S1ddons, on Flickr rev h complete_bare 800px by Sarah S1ddons, on Flickr

rev h complete_bare 800px by Sarah S1ddons, on Flickr rev i complete 800px by Sarah S1ddons, on Flickr

rev i complete 800px by Sarah S1ddons, on Flickr